Overview: The KUKA KR IONTEC is a cutting-edge robotic solution offered by the renowned brand KUKA. This robot seamlessly integrates a compact design with an expansive working envelope, making the most efficient use of space. It boasts a small footprint and is equipped with a waterproof and dustproof in-line wrist, ensuring versatility across various applications. The addition of protected motors enhances its adaptability, while the optional Foundry variant extends its operational capabilities to high-temperature environments.

Benefits:

- Sustainable Cost Efficiency: The KUKA KR IONTEC offers a cost-effective solution that maximizes your investment’s value over time.

- Maximum Flexibility: With its versatile design, this robot can be utilized in a wide range of tasks and industries, providing adaptability to evolving needs.

- Maximum Availability: The robot’s reliability and robust design ensure minimal downtime, translating to increased productivity and operational continuity.

- Optimized Design: The integration of a compact form factor and extensive working envelope optimizes space utilization and enhances overall efficiency.

- Adaptation to Harsh Environments: The optional Foundry variant’s extended temperature range allows the robot to excel even in extremely hot conditions.

Features:

- Sustainable Cost Efficiency: The KUKA KR IONTEC offers energy-efficient operation and a long service life, contributing to overall cost savings.

- Maximum Flexibility: Its versatile design accommodates various mounting positions, enabling integration into diverse production setups.

- Maximum Availability: The robot’s durable construction and low-maintenance components ensure consistent performance and reduced downtime.

- Optimized Design: The robot’s compact footprint is paired with an expansive working envelope, making it an ideal solution for space-constrained environments.

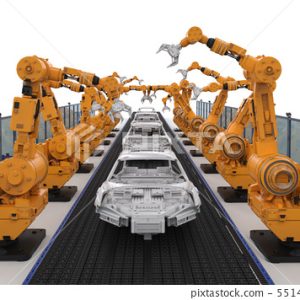

Applications:

- Automated Manufacturing: The KUKA KR IONTEC is well-suited for tasks such as material handling, assembly, and welding within manufacturing facilities.

- Logistics and Warehousing: With its compact design and versatility, the robot can efficiently manage inventory, order fulfillment, and package handling.

- High-Temperature Environments: The optional Foundry variant finds its application in industries such as metal casting, where extreme temperatures are present.

- Electronics Production: The robot’s precision and adaptability make it an excellent choice for assembling delicate electronic components.

- Automotive Industry: From assembly lines to painting processes, the robot’s flexibility and robustness contribute to streamlining automotive manufacturing operations.

Reviews

There are no reviews yet.